What You Will Learn

In this blog, we put together 11 of the most practical and best warehouse wall styles to help you decide on what to you in your warehouse. With ideas ranging from basic curtains and divisions to strong walls and insulated walls, learn how to properly divide workspaces, control temperature, increase safety, and maximize productivity at your facility.

Table of Contents

VINYL CURTAIN WALLS

Standard

Freestanding

Mesh

Fabric Building Warehouses

FABRIC CURTAIN WALLS

Standard Fabric Curtain Walls

Industrial Canvas Walls

STRIP

Standard

Welding

Anti-Static

INSULATED CURTAIN WALLS

Modular Panel

Retractable

MODULAR WAREHOUSE SEPARATION WALLS

Modular Warehouse Separation Walls

PREFABRICATED/PRE-FINISHED WALLS

Pre-Finished Walls

STICK-BUILT WALLS

Stick-Built Walls

PERMANENT WAREHOUSE WALLS

Drywall

Concrete Walls

Stud Walls

MESH PARTITIONING

SteelMesh

PALLET RACKING WITH VINYL BACKING

Pallet Rack Curtains

PORTABLE WAREHOUSE DIVIDERS

Portable Fabric Dividers

Portable Vinyl Dividers

Pipe And Drape

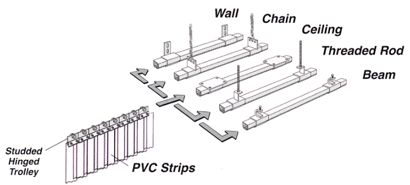

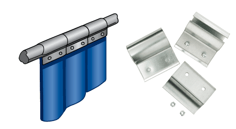

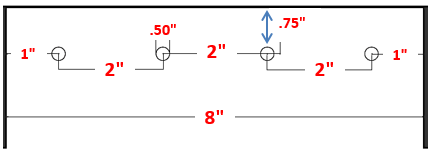

What to do when you can't attach to the ceiling?

Entry and Exit Points

Summary

Vinyl Curtain Walls

Standard

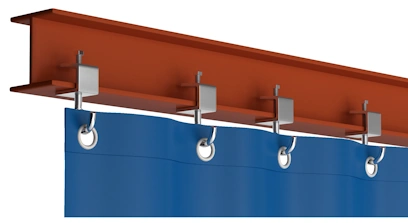

Warehouse divider curtains are a flexible and reasonably priced answer for maximizing the use of warehouse space. Depending on your need, these are easy to install and removable anytime needed. Since it regulates temperature and humidity in the enclosed area, it also helps cut the energy use in your building.

They help hide smoke, paint overspray, and dust, therefore improving the working surroundings. Perfect for many uses, including cold storage and distribution hubs, warehouse divider curtains provide a versatile and fairly cost approach to increase your output.

The Pros and Cons

Pros of Warehouse Divider Curtains:

- Energy Efficiency: Cut your bills for warehouse heating and cooling.

- Space Optimization: Close off unneeded floor area for next usage.

- Cost Effective Solution: Vinyl warehouse dividers cost less than fixed walls.

- Enhanced Air Quality: Contains dust, paint overspray, and smoke from different industrial operations.

- Improved Working Condition: Keep the workplace comfortable for employees.

Cons of Warehouse Divider Curtains:

- Durability: Depending on the material, these curtains might be affected by tears, cuts, wear and tear from frequent handling or heavy machinery.

- Aesthetics: Although some aesthetically pleasing curtain options are available, they might not quite match the overall style of your warehouse.

- Airflow: Some vinyl curtains have ventilation choices, but solid vinyl can make it hard for air to flow and the workplace to be less comfortable.

- Static Electricity: Vinyl can make static electricity, which can attract dust and give workers small shocks, which could damage sensitive electronics.

Freestanding

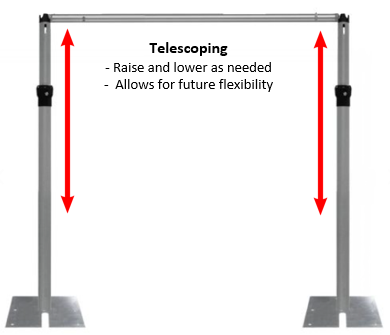

Industrial Freestanding Curtains are a strong and flexible option for situations where hanging them from above is not possible or desired. You may modify every detail about these freestanding curtains to fit the needs of your building. They can be set up in any way you want because they come in any width and any height up to 15 feet.

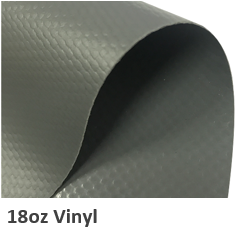

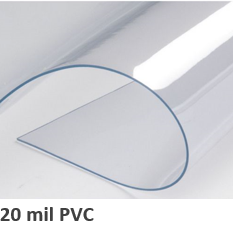

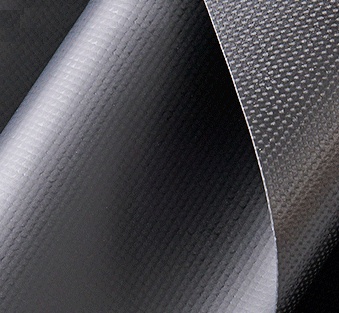

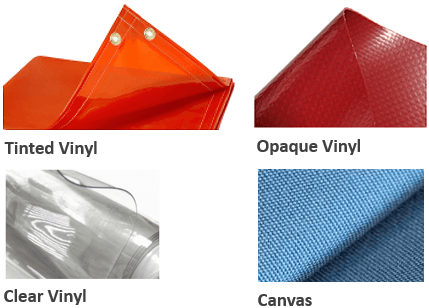

You can pick from many colors and materials, such as 18oz Reinforced Vinyl for curtains that are opaque and 20mil Vinyl for curtains that are see-through. Entry options such as strip curtains can also be added for frequent access.

The Pros and Cons

Pros of Freestanding Curtains:

- Easy-to-Install: You don't need any special tools. The bolt-together design makes it easy to put up, and roller hooks or zip ties make it easy to hang curtains.

- Affordable: Costing roughly one-third of the cost of other dividers like hard walls or panels.

- Separate Workers: Industrial curtains that stand alone are great for keeping workers separate while they build, wash, package, or do many other tasks.

- Noise-reduction: Because they are made of thick PVC, industrial curtains block out noise, which makes the workplace more comfy.

- Versatility: They are easy to move when the floor plan of your warehouse changes. This gives you the freedom to change your floor plan without having to make expensive changes to the structure of your building.

Cons of Freestanding Curtains:

- Durability: Vinyl curtains are durable, but they can get holes and tears, especially in places with a lot of foot traffic or near heavy machinery.

- Aesthetics: Freestanding curtains may work, but they might not always be the most attractive choice.

- Stability: Even curtains that stand alone can fall over sometimes, especially if they are not properly held or if they are hit by strong air currents or objects.

- Visual Obstruction: If the screen is made of an opaque or clear material, it can make it very hard to see, which could affect safety and productivity.

Mesh

One really excellent solution for dividing your warehouse is Industrial Mesh Curtains. By separating your warehouse into specialized zones for various tasks, these flexible divisions offer a quick and simple approach to increase workflow.

Moreover, mesh curtains improve ventilation, which is rather important in warehouses where heat accumulation or inadequate airflow is possible. Excellent airflow made possible by the mesh material helps to keep small pests and insects out rather successfully.

These curtains give optimum versatility as well. As your demands change, you can always go ahead and change your warehouse floor plan. Mesh curtains may be placed, changed, or removed easily as needed making it ideal for dynamic workplaces.

The Pros and Cons

Pros of Industrial Mesh Curtains:

- Keep Bugs at the Bay: They work like a strong screen door to keep bugs, birds, and other animals away from your things.

- Maximize Your Space: A great option dividing your warehouse into different areas without having to build walls.

- Energy Efficient: Saves you more money by keeping your place warmer in the winter and cooler in the summer.

- More Affordable Option: Using mesh curtains as divider for your warehouse is relatively cheaper than building an actual wall.

- Improved Working Conditions: Mesh reduces sunlight glare so it provides better working environment for workers.

Cons of Freestanding Curtains:

- Sound Insulation: While a great option for dividing your area, it can offer minimal sound insulation and may not be ideal for warehouses with loud machineries.

- Reduced Privacy: Since mesh curtains are see through, it may not offer much privacy compared to other solutions.

- Temperature Control: May not be an ideal option for warehouses where goods need to be stored at a certain temperature.

- Possible Damage: Mesh curtains are durable; however, it is prone to being torn or damaged by sharp objects.

- Maintenance: Even though mesh panels are usually easy to clean, they can get dirty and dusty over time, especially in busy industrial settings. Depending on the height and shape of the curtains, they may need special tools or more frequent care to be cleaned thoroughly than solid, smooth-surfaced dividers.

Fabric Building Warehouses

Fabric building divider curtains are a very flexible and inexpensive way to make warehouse and industrial areas work better. Instead of fixed, rigid walls, these curtains can be moved around to divide spaces in a way that suits your needs.

They are inexpensive, easy to set up, and offer many benefits. They are great at making clear work areas, keeping the air, noise, and dust under control, and keeping clean, separate areas within a bigger space. Fabric curtains are much cheaper than fixed walls and work just as well for controlling humidity, keeping temperatures separate (up to 40 degrees Celsius), and even keeping paint overspray or smoke inside.

Basically, fabric building divider curtains are a flexible and inexpensive way to organize production, improve workflow, and make the workplace safer and more comfortable.

The Pros and Cons

Pros of Fabric Building Dividers:

- Building Partition: Depending on how you want to organize your production, you can quickly split the building into several areas.

- Temperature Zoning: Lets you create temperature zones for goods that needs to be stored in a specific temperature.

- Humidity Control: Easily control humidity levels for storages of food products and better manufacturing processes.

- Separating Tenants: Divides your warehouse easily so you can lease out other parts to tenants.

- Sound Insulation: Due to its thick batting, fabric building curtains are ideal to use in areas with loud machineries as it provides better noise control.

Cons of Fabric Building Curtains:

- Durability: These curtains may be susceptible to rips, cuts, and wear and tear from heavy machinery or frequent handling, depending on the material.

- Maintenance: To maintain their aesthetic appeal and practicality, curtains may require regular washing and attention.

- Airflow: Some vinyl curtains have ways for air to flow through them, but thick vinyl might block airflow and make the workplace less comfortable.

- Static Electricity: Vinyl can make static electricity, which can settle on dust and give workers small shocks that could damage sensitive equipment.

Fabric Curtain Walls

Standard Fabric

Commercial fabric curtains are great for warehouse showrooms, dividing up places in a building, or even decorating for events! If you want to add a bit of class to your space, this is the best option because it can be used for both interior and exterior.

Usually, these curtains are composed of premium materials that satisfy industrial criteria and are fire-resistant. They come in many fabrics and are both light and robust. These curtains not only look good but also serve really well since they prevent the transmission of dust, bacteria, and even diseases. Since they can be altered to fit any room, long-term commercial fabric curtains are a wise investment.

The Pros and Cons

Pros of Commercial Fabric Curtains:

- Fire-resistant: These curtains meet the fire-retardant standards making it safe to use on any kinds of business.

- Durability: Commercial Fabric Curtains are built to last as they are made from tough materials like vinyl and velour.

- Extra Protection: Due to its thick materials, it's a great way to prevent dust, infections, and other harmful elements from getting inside your area.

- Versatile: Fully customizable to fit any space and can be used in many ways such as for privacy, noise reduction, or stage curtains.

- Made in the USA: Proudly made from the US to support local businesses.

Cons of Commercial Fabric Curtains:

- Maintenance: Due to its large size, cleaning and maintaining them may be challenging. It's heavy as well so maintaining it could be challenging too.

- May Not Be Budget Friendly: Fabric curtains alone, depending on the material, is already a bit expensive. Given that commercial fabric curtains are mostly used for showrooms and events, customization to fit your need may increase cost.

- Limited Automation: Because of their size, these curtains can't be fully automated, so workers have to put in extra work when they're being used, especially at events.

- Installation: Although easy to install, it can be challenging to install it since it is quite heavy.

- Can Block Natural Light: Depending on type of fabric used, they can block natural sunlight from coming inside your area.

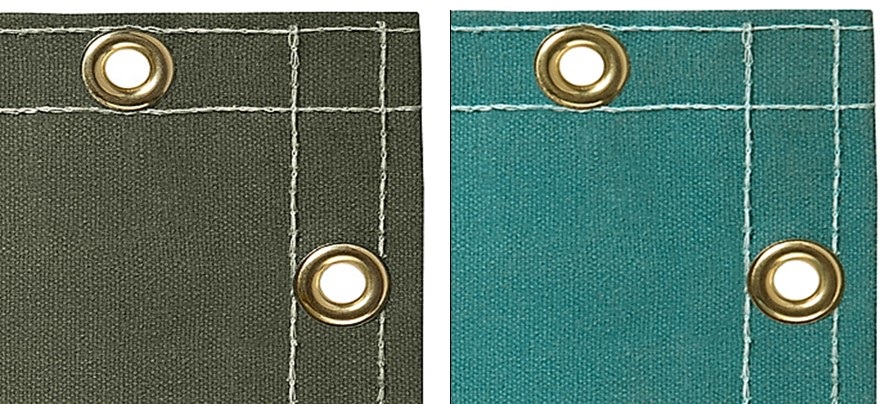

Industrial Canvas

Industrial Canvas Curtain is a great choice for places that get a lot of heat because it stops fires from spreading, making your building safer for your employees. The high-quality material used to make these curtains can stand up to tough conditions. This is a great choice for factories, shops, and warehouses because it can divide rooms, keep out noise, light, and dust, and protect against welding sparks. These curtains have reinforced ends and grommets on them so that they are safe to hang. They are easy to put up and can be made in any size you need. You can make your factory safer and more productive through this solution.

The Pros and Cons

Pros of Industrial Canvas Curtains:

- Air flow: Industrial canvas curtains are made of woven fabric. This lets air pass through them, making them good for places that need to ventilate.

- Natural Material: A good choice for businesses that want to reduce their impact on the world.

- Aesthetic: Compared to vinyl, canvas often has a more natural and less industrial look. This can be helpful when it comes to looks, customer service, or cases where presentation is important.

- Fire Resistance: Industrial canvas curtains can be treated with chemicals that make them less likely to catch fire and stop flames from spreading, so they can be used in places where welding or flame work is done.

Cons of Industrial Canvas Curtains:

- Water Absorption: Canvas naturally soaks up more water than vinyl, and it might not work as well in very wet situations, even if it can be treated to be waterproof.

- Harsh Conditions: May not be the best option for places where it is regularly exposed to harsh chemicals, oils, or extreme weather.

- Weight: Because canvas is usually heavier, it may take more work to put up, take down, or make changes to it.

Strip Walls

Standard Strips

Strip curtain walls are a great way to divide spaces while also keeping the access between spaces easy. These curtain walls are made from strong, vinyl strips which are usually used to close off areas to help keep the temperature even, lower the noise, and stop germs from spreading. They are great for loading docks, factories, and warehouses because they have all the benefits of regular walls and lets workers move easily from one place to another without compromising privacy. They come in different sizes and can be put together in any way that makes the most sense for your business or industrial space in terms of flow, safety, and comfort.

The Pros and Cons

Pros of Strip Curtains:

- Energy Efficient: Strip curtains help regulate temperatures by preventing the loss of warm or cool air. This is recommended in buildings with walk-in freezers, coolers, or other places that need to keep a certain temperature.

Improved Working Conditions: Workers can move from one area to another without having to open and close doors all the time. In busy places where things need to be moved around a lot, this is helpful. This is ideal in busy buildings where things need to be moved around a lot. - Protection from Pest: Keeps areas clean and free of bugs, rodents, and airborne pollutants lowering chances of contamination.

- Sound Insulation: Reduces noise between areas giving workers a more quiet and pleasant workplace.

- Affordable: Strip curtains aren't as expensive compared to building solid walls and are a better way to split your warehouse without breaking the bank.

Cons of Strip Curtains:

- Aesthetic: Although strip curtains offer flexibility in customization, they may not be ideal for buildings that require aesthetic presentations.

- Environmental Issues: Certain PVC strip curtains might include dangerous chemicals that could emit fumes which can affect air quality inside the warehouse.

Welding

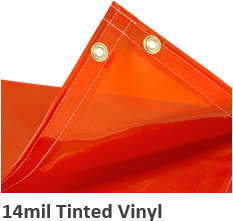

For warehouses with welding equipment, welding strip curtains are an ideal option. Made of PVC strips hanging together, these curtains block the dangerous UV rays generated during the welding operation. For both welders and surrounding persons, this significantly decreases eye damage and skin burns. Apart from UV protection, they also help to divide welding zones from non-welding regions thereby covering your other employees operating in different locations. They may be tailored to match different welding environments and installed readily. This is most certainly something you should give thought if you are seeking for a less expensive way to split your warehouse with welding stations.

The Pros and Cons

Pros of Welding Strip Curtains:

- UV Blocking: Protects your welders by blocking harmful UV Rays that are produced during the welding process.

- Maximize Your Space: Welding Strip Curtains are also used to welding areas from non-welding areas to create a more efficient and comfortable working environment for your workers.

- Easy to Install: These curtains are easy to install and there's no need for you to hire professional installer.

- Affordable Option: A less expensive alternative than building solid walls.

- Maintenance: Easy to maintain and clean in case it gets dirty.

Cons of Welding Strip Curtains:

- Environmental Issues: Some PVC might include harmful chemicals that could release fumes influencing the indoor air quality in the warehouse.

- Aesthetic: Although welding strip curtains can be customized, they may not be ideal for buildings that require aesthetic presentations.

Anti-Static

Anti-static strip curtains are a special kind of screen that keeps static electricity from building up in warehouses with sensitive areas. The materials used to make these curtains are conductive, which means that static electricity can safely fall to the ground. This is very important in places where static electricity can be very dangerous such as electronics areas, pharmaceutical warehouses and chemical warehouses. This adds an extra layer of protection to your employees and ensures safety of your warehouse operation in general.

The Pros and Cons

Pros of Anti-Static Strip Curtains:

- Protection from Electrostatic Discharge: This keeps medicines, electronics, and other things that are easily hurt by static electricity from getting broken.

- Safety: It helps keep sparks from starting fires and explosions.

- Improved Cleanliness: Keeps dust, trash, and other dirt out of certain building areas, which makes the whole place cleaner and lowers the risk of product contamination.

- Cost-Effectiveness: In many workplace situations, anti-static strip curtains are a cheaper way to control electrostatic discharge than more complicated methods.

Cons of Anti-Static Strip Curtains:

- Not very durable: It can be broken by regular wear and tear, or chemicals.

- Possible Grounding Problems: To protect against electrostatic discharge, it is very important to make sure that the anti-static curtains are properly grounded.

- Limited Visibility: Some options are clear, but they may still make some things hard to see, which could be dangerous or slow down work.

- Maintenance: Cleaning and upkeep must be done on a regular basis.

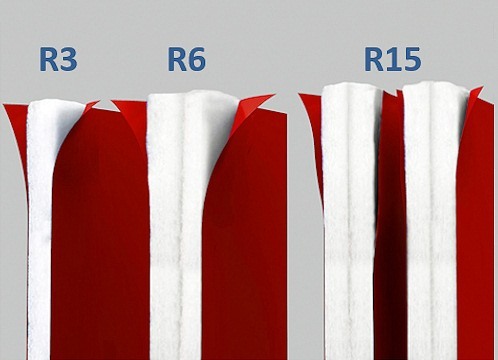

Insulated Curtain Walls

Modular Panel

If you have to control the temperature or humidity in some areas of your warehouse, modular panels are a fantastic solution. These flexible panels help you split your area readily for a more effective manufacturing process. Unlike typical walls that remain in place, modular panels are quite adaptable. If you have to, they are simple to walk about or even remove totally. As your company expands, this enables you modify the layout of your warehouse. Moveable panels' cheap nature is their best feature. Usually less costly than installing permanent walls, they are a great approach to create temperature-regulated sections in your factory without running large expenses.

The Pros and Cons

Pros of Modular Panels:

- Temperature Zoning: These panels allow you to establish temperature zones to keep items at varying degrees or to divide areas per operation thereby improving the comfort of the workplace.

- Humidity Control: Control of humidity in your facility will help both storage of your goods and improved manufacturing operations.

- Maximize Your Space: Using these panels, separate spaces based on their use. These will also allow you to utilize your warehouse and let others lease it out.

- Sound Insulation: Due to the thick batting, modular panels can manage noises within the facility so loud sounds coming out from machines will not disturb other workers.

- Cheaper Option: Installing modular panels is a cheaper solution in the market rather than building solid walls.

Cons of Modular Panels:

- Potential for Air Leakage: Improper installation and sealing may leave gaps between panels allowing air escape. This could endanger temperature control and increase energy expenditures.

- Aesthetic:The appearance of modular panels may not be as pleasing as standard solid walls depending on the particular panel design and finish.

Retractable

For buildings needing temperature zoning, retractable insulated curtains is an ideal solution. This is a cheaper option for partitioning than building solid walls. Since they are easy to install and may be pulled down anytime allowing you to re-organize your floor plan as needed, it is also more practical to invest in these. These curtains are made out of vinyl which makes them easier to wash and clean should they get soiled. It can also endure harsh environment and absorbs no kind of fluids or stains, so you can quite guarantee that it will last. Retractable insulated curtains are absolutely worth looking at if you want a quick and practical approach to divide your production spaces and storages at your warehouse.

The Pros and Cons

Pros of Retractable Insulated Curtains:

- Energy Saving: Helps regulate temperature by preventing the loss of warm or cool air. This means lower energy consumption, and lesser energy bills.

- Maximize Your Space: Lets you enclose spaces and lease out other spaces of your warehouse that are not needed.

- Noise Reduction: Because they are made out of thick materials, they block out noises and makes it ideal for areas with loud machineries.

- Maintenance: The material doesn't absorb liquids or stains, so it is easy to clean.

Affordable: The cost of installing retractable insulated curtains is on par from installing regular solid walls.

Cons of Retractable Insulated Curtains:

- Aesthetic: Although strip curtains offer flexibility in customization, they may not be ideal for buildings that require aesthetic presentations.

- Environmental Issues: Certain PVC strip curtains might include dangerous chemicals that could emit fumes which can affect air quality inside the warehouse.

Modular Warehouse Separation Walls

Modular Warehouse Separation Walls

When you have to separate your facilities across processes, Modular Warehouse Separation Walls are a great option. It can also be used as a dividing your warehouse into smaller spaces if you wish to rent or lease it out. These walls are simple to install and would not disturb your production or downtime, so they are a practical alternative than building solid walls. Furthermore, these walls are highly customizable since you have options to add windows, doors, and electrical outlets all around your area. Modular warehouse separation walls are something you really should give some thought if you are seeking for another choice for your facility.

The Pros and Cons

Pros of Modular Warehouse Separation Walls:

- Easy to Install: They are quick and easy to install and won't disrupt your production time making it a practical option rather than building solid walls.

- Highly Customizable: You have an option to add windows, doors, and electrical outlets. They can be built depending on your needs.

- Maximize Your Space: These walls let you separate your warehouse into small spaces in case you wish to rent or lease it out.

- Improved Organization: Lets you assign dedicated work areas depending on processes making your business process more efficient and more organized.

- Affordable: A cheaper alternative option rather than building solid walls.

Cons of Modular Warehouse Separation Walls:

- Limited Durability: May not be as durable as solid walls and may also require more frequent repairs or replacement.

- Air-leakage: Gaps in between panels can allow for air to leak out of the area which affects temperature on spaces where temperature needs to be regulated.

- Limited Sound-Proofing: May not provide as much sound insulation than regular solid walls. This may cause distraction to other work stations especially of you have loud machineries.

Pre-finished Walls

Pre-finished Walls

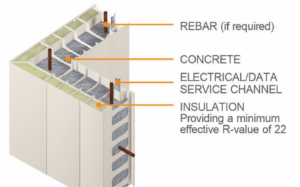

Another choice you could want to take into consideration in case you are looking for a quick and simple solution for your warehouse needs is pre-finished walls. Built off site in a controlled manufacturing setting these wall panels are then delivered to your location for installation. Since it is already made when it arrives at your site, this saves you a lot of time. This also helps you avoid manpower shortages and construction delays since they are manufactured off site. Pre-finished walls are a great choice if you want a faster and more practical alternative for your warehouse needs.

The Pros and Cons

Pros of Pre-finished Walls:

- A Cheaper Option: This solution is cheaper than building solid walls in the long run.

- Custom-Built: These walls are made to order to fit your business needs so you maximize your office or warehouse spaces better.

- Quick and Easy to Install: They area made off-site in a factory and delivered at your location already built which eliminates the waiting time for construction within your warehouse space. Saves you both time and money.

- Low-Maintenace: Easy to maintain since it is built of solid concrete. It will also not rust, corrode, flake, peel or, rot.

- Durability: Made out of solid concrete so it is made to last.

Cons of Pre-Finished Walls:

- Flexibility: Once these walls are built and delivered, making changes to the design or material will be challenging and definitely costly.

- Potential Damage During Transport: There's a risk of damage to the walls during transportation which can delay your construction and can be an added cost on your end.

- Manufacturing Schedule: While manufacturers usually provide lead time for manufacturing and delivery, there may still be unforeseen delays in between processes which can also delay your processes.

- Higher Initial Investment: The initial investment for using these walls is higher than building a solid wall on site.

- Transportation Challenges: Transporting large and heavy panels can be challenging and can also cause unforeseen delays.

Stick-built Warehouse Walls

Stick-Built Walls

Stick Built Walls are a great option in situations wherever the space will remain long-term after newly built construction is completed. These refer to walls created piece-by--piece on-site rather than from pre-finished solutions. They are commonly used in offices, bathrooms, lobbies, conference rooms, and other spaces needing reinforced separation are these walls. Stick-built buildings are created completely at the construction site, unlike modular or prefabricated construction whereby components are built off-site and transported for installation. Though there are other solutions available now, some still choose this one first because of its scalability and wide design possibilities.

The Pros and Cons

Pros of Stick Built Walls:

- Flexibility: Since they are built on site, any changes that needed to be applied can be applied instantly.

- Adaptability: They can be made to adapt to irregular office or warehouse space shapes.

- Readily Available Materials: Materials used are usually lumbers so they are readily available from local suppliers which reduces the potential delay in construction due to delivery issues.

Cons of Stick Built Walls:

- Timeline: Unlike just laying already completed wall panels, building on-site can take more time.

- Weather Delays: Unexpected weather can cause building to be slowed down.

- Potential Human Error: You will have to engage qualified personnel to ensure the installation runs smoothly. This can imply more expenses for you and errors committed by others during construction.

Permanent Warehouse Walls

Drywall

Using drywall partitioning is one method to build interior walls. Made lightweight, installers will find this easier compared with brick and mortar. During installation, it produces minimal dust which keeps your area neat and tidy. Usually, installation can be finished within a day, but it would still depend on the size of your warehouse. Depending on the materials used, drywall also offers better sound proofing. They can resist high temperatures and be made fireproof. Drywall is an excellent choice if you want a faster and simpler answer for your warehouse needs.

The Pros and Cons

Pros of Drywall:

- Cost Effective: Compared to building materials like concrete or brick, it is less expensive for splitting your warehouse.

- Installation: Their simplicity and speed help to reduce yoru downtime and enable early operation of your warehouse.

- Customizable: Allow your warehousing requirements to guide your design.

- Maximize Your Space: Divide your area into small office areas so you might rent or lease it for additional income.

Cons of Drywall:

- Durability: It doesn't last as long as concrete or brick, so it might not be a good choice for places with a lot of foot traffic or heavy impact.

- Structural Limitation: It might not be good for holding heavy loads or building walls that hold weight.

- Potential Damage: Not as strong as traditional walls so they are prone to damage, and they are not pet resistant.

Concrete Walls

Concrete Wall Panels are a more flexible and affordable option for your warehouse partitioning needs that you might want to explore into. They are among the most ideal options for warehouses with toughest conditions since they are known for their strength. Perfect for agricultural uses and storage facilities, these panels resist chemical damage and are easy to clean. They also offer a sturdy and long-time solution for your partitioning needs. The concrete panel walls divide your building into smaller areas you can utilize anyway you like. Since they are dependable, cost-effective, and customizable to your demands, concrete wall panels are a good option for search for a solution to your warehouse need.

The Pros and Cons

Pros of Concrete Walls:

- Moisture: Concrete wall panels are moisture resistant making them ideal for storage of goods.

- Chemical Exposure: They are ideal for any industrial applications since they resist damages from chemicals.

- Durable: These walls are built to last and can withstand weather conditions like hurricane or earthquakes.

- Low-Maintenance: Since it is concrete, it doesn't require much maintenance and cleaning.

- Strength: Strong enough to support multi-story facilities.

Cons of Concrete Walls:

- High Initial Investment: Although it is considered cost-effective in the long run, the initial investment for building concrete walls in your warehouse is higher compared to other solutions previously mentioned.

- Time Consuming: All kinds of concrete walls require careful planning and there is a great risk of delay resulting from unanticipated events including material supplier problems or, in the case of pre-cast concrete, transportation and handling delays. This means longer downtime for your warehouse production.

- Manual Labor: To guarantee appropriate installation, you must hire skilled professionals in building these concretes.

- Modification: Once your facility is completed and set-up, re-design and re-arranging it can be difficult since they are permanent walls.

- Repair: Damage is unavoidable for concrete walls even though they are built for harsh conditions. Repairing them in case of damage might be rather difficult and expensive.

Stud Walls

Stud Walls could potentially be something you want to look at if you would like to divide your warehouse from floor to ceiling in easily accessible areas. Usually composed of either wood or metal, stud walls are then covered with sheathing materials like plywood using framework. Since they can be custom built according to your needs and less expensive than standard concrete walls, they are an appropriate solution for your warehouse.

Unlike other concrete wall solutions, stud walls are faster to build and install since they do not rely on agents like cement to dry and harden up to finish. Given its simplicity and economic benefits, stud walls are absolutely a perfect choice for your partitioning needs.

The Pros and Cons

Pros of Concrete Walls:

- Moisture: Concrete wall panels are moisture resistant making them ideal for storage of goods.

- Chemical Exposure: They are ideal for any industrial applications since they resist damages from chemicals.

- Durable: These walls are built to last and can withstand weather conditions like hurricane or earthquakes.

- Low-Maintenance: Since it is concrete, it doesn't require much maintenance and cleaning.

- Strength: Strong enough to support multi-story facilities.

Cons of Concrete Walls:

- High Initial Investment: Although it is considered cost-effective in the long run, the initial investment for building concrete walls in your warehouse is higher compared to other solutions previously mentioned.

- Time Consuming: All kinds of concrete walls require careful planning and there is a great risk of delay resulting from unanticipated events including material supplier problems or, in the case of pre-cast concrete, transportation and handling delays. This means longer downtime for your warehouse production.

- Manual Labor: To guarantee appropriate installation, you must hire skilled professionals in building these concretes.

- Modification: Once your facility is completed and set-up, re-design and re-arranging it can be difficult since they are permanent walls.

- Repair: Damage is unavoidable for concrete walls even though they are built for harsh conditions. Repairing them in case of damage might be rather difficult and expensive.

Mesh Partitioning

Steel Mesh or Wire panels

Steel/Wired Mesh is yet another option for facilities partitioning. These are created from hard wire interlocked to create grids with spaces between the wires that are wide enough for you to view what is inside the enclosed place and also stop anything from passing through.

Mostly utilized in supermarkets' warehouses or facilities needing lots of people's movement and machining, these are they’re perfect since they can be built exactly to meet your needs and provide an extra level of protection to high risk areas.

Steel/Wired Mesh could be a flexible solution for your warehouse's partitioning needs.

The Pros and Cons

Pros of Steel Mesh/Wired Panels:

- Injury: In storage areas where goods and products are stacked, these panels provide a safe access to these areas without the danger of being hit by falling objects.

- Product Damage: Aside from protection to your personnel, they also add protection to your goods and products from falling.

- Theft: While it is mainly used as protection to anything inside the enclosed space, they also prevent theft by not letting unauthorized access to the enclosed area.

- Partitioning: They can be used to create small partition and divide your processes into small areas without blocking the view.

- Resistance to Heat & Water: They are resistant to fire, heat, moisture and water so it is durable and are great for sprinkler systems.

Cons of Steel Mesh/Wired Panels:

- Sound Insulation: Because of its structure, it is not suitable for areas where soundproofing is needed.

- Privacy: It was built for you to see what is inside the enclosed area and with that said, if it's going to be used as partition for warehouse to create small offices, limited privacy will be provided.

- Aesthetics: May not be the most aesthetically pleasing solution and not suitable for facilities where presentation is important.

- Limited Capacity: Not ideal for supporting heavy loads

- Potential Safety Hazards: Regular checking and maintenance may be required to ensure no share edges or damages are on the wired mesh because if not repaired sooner, it could be hazardous to your workers.

Pallet Racking with Vinyl Backing

Pallet Rack Curtains

Pallet Rack Curtains are used to hide contents of the pallet rack to create a cleaner look or simply provide privacy to the goods that are stored in the enclosed space.

They are usually made of 18 oz Vinyl which are strong and durable material. They can be cut and customized to fit your needs and they can also come in different colors.

Pallet Rack Curtains are a great option if you are looking for a quick and easy solution for your partition needs since they are quick and easy to install. You will just walk them from side to side and the curtain will roll on its own. These curtains are one of the most practical and affordable solutions you might want to look at.

The Pros and Cons

Pros of Pallet Rack Curtains:

- Privacy: Since the main material used is Vinyl, it could increase privacy to whatever you are enclosing in the area.

- Maximize Your Space: Divide your storage facility into different spaces for products that you need to separate from each other.

- Temperature Control: Insulated Vinyl is suitable for racks with products that needs to be stored in a certain temperature.

- Easy to Install: There's no need to hire a professional installer since it is easy to install. They can also be taken down anytime when it is not needed anymore.

- Affordable Option: A less expensive alternative than building solid walls.

Cons of Pallet Rack Curtains:

- Visibility: These curtains could block the outside view, so making visually inspections of products can be quite challenging.

- Environmental Issues: Some PVC might include harmful chemicals that could release fumes influencing the indoor air quality in the warehouse.

Portable Warehouse Dividers

Portable Fabric Dividers

Another option for your big warehouse facility is to use Portable Fabric Dividers. Quickly split areas into small, multipurpose spaces in minutes! If you need to change the layout of your facility often, these are great because they are simple to set up and take down quickly when not in use.

These dividers are made of fabric, so they are light, sturdy, and highly customizable. Depending on the type of wall you use, they give your employees more privacy and make the space look better.

The Pros and Cons

Pros of Portable Fabric Dividers:

- Easy to Install: Made of polycarbonate materials, these dividers are lightweight and easy to install, which is perfect for facilities that often change their layout.

- Cheaper Option: They are a cheaper option compared to other solutions available, like building a solid wall for dividing your space.

- Aesthetic: They are highly customizable, so the dividers themselves may give your space a more attractive and aesthetically pleasing look. This is perfect for facilities that accommodate customers, and presentation is a big thing.

- Versatile: They come in different sizes and shapes and can be used not only in warehouses but also in regular offices or even residential buildings.

- Maintenance: They are easy to clean and maintain.

Cons of Portable Fabric Dividers:

- Sound Insulation: Though some suppliers provide soundproofing add-ons, this type of divider may still not completely trap sounds due to some openings that come with it as well as its material. With this, it may not be suitable for warehouses with loud machinery, as it will cause distraction to other workers.

- Sustainability: Even though they come in different size and shapes, it may still not cover all parts of the areas that you need to cover and in the long run, you may need to change it to something more suitable to your warehouse.

- Privacy: Although it provides privacy, it may not give you full privacy unlike other dividers because of its openings.

Portable Vinyl Dividers

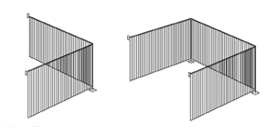

Portable Vinyl Dividers are perfect for industrial workplace separation. Unless they can guarantee the safety of their workers, many industrial enterprises, offices, and plants are obliged to close during a viral outbreak. These dividers are therefore helpful since they will keep employees at a safe social work distance from one another for management of contamination.

Along with many different combinations, the dividers can create a single separating wall, a two-sided enclosure, three side enclosure, or four-sided enclosure. The portable vinyl dividers are a fairly quick fix when it is needed to keep people working at safe distances.

These dividers are made of PVC, so they are easy to maintain and safe to clean with disinfectant without harming its colors.

The Pros and Cons

Pros of Portable Vinyl Dividers:

- Privacy and Safety: Portable Vinyl Dividers adds privacy and provides safe distance from one work area to another and preventing any viral outbreak.

- Maximize Your Space: Increased productivity since workstations are properly divided.

- Maintenance: Since the material is made of vinyl, they are easy to clean and maintain.

- Easy to Install: There's no need to hire a professional installer since it is easy to install. They can also be taken down anytime when it is not needed anymore.

- Affordable Option: A less expensive alternative than building solid walls.

Cons of Portable Vinyl Dividers:

- Visibility: These curtains could block the outside view, so making visually inspections can be quite challenging.

- Environmental Issues: Some PVC might include harmful chemicals that could release fumes influencing the indoor air quality in the warehouse.

Pipe and Drape

Like massive, configurable Lego structures for curtains, Pipe and Drape systems are extremely flexible, and they perform well for both temporary and permanent setups.

They work as a framework for your divider needs, so you can easily customize its layout depending on your needs. For warehouses that quickly changes their layouts, this is very ideal.

Usually sold separately, these pipe and drape systems let you choose the kind of fabric you will use based on your warehouse requirement, making them an excellent choice if you are looking for an affordable and versatile solution for your warehouse dividing needs!

The Pros and Cons

Pros of Pipes and Drapes:

- Flexible: You are free to do whatever layout you prefer and make sure it fits your needs.

- Choice of Fabric: You also have freedom to choose what type of fabric are you going to use for the actual cover of these panels.

- Affordable: This is a great option if you are tight in a budget but wants a durable dividing solution for your warehouse facility.

- Easy to Install: There is no need to hire a professional installer since they are easy to put up and can also be taken down quickly whenever it is not needed anymore.

- Maximize Your Space: Divide your warehouse space easily with these pipes and drapes. This is a great option for you if you have to change your layout often.

Cons of Pipes and Drapes:

- Temporary Solution: Pipe and Drapes are a great quick fix to your warehouse dividing needs but in the long run, you may have to replace it to a more permanent solution especially if your warehouse demands change.

- Stability: Unlike other permanent dividers, pipes and drapes system may not be as stable especially if not properly secured or weighted. Because of this, it may not be the most suitable solution for busy warehouse areas.

- Aesthetics: Although the fabric is customizable, the panels itself may not be aesthetically pleasing to the eye and is not a great option for spaces that needs presentation.

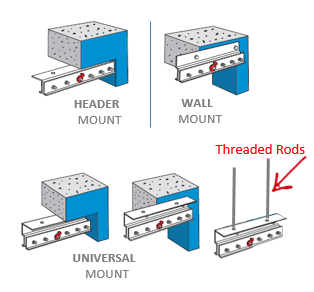

What to do when you can't attach dividers to the ceiling?

There are still a lot of ways to divide your warehouse and make the most of the space you have, even if you can't attach them to the ceiling. In manufacturing facilities overhead cranes are popular because they are quick and easy to use to load, unload, and move materials. You could add special curtains to overhead cranes and connect the curtains to the crane itself to make it perform more efficiently. Heavy-duty industrial curtains are a better way to keep things separate while still letting the crane do its job. Mezzanine Curtains are another choice. Industrial mezzanine blinds are made just the way you want them. The curtains work great if you need to quickly build a wall or close off the area above an office in your warehouse.

To learn more about these options, click the button below:

Entry and Exit Options

Roll Up Doors

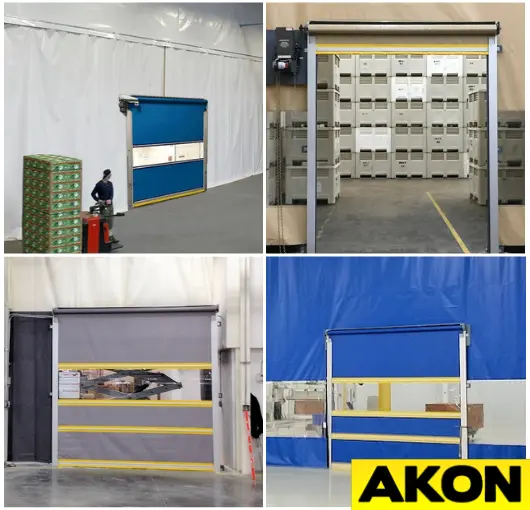

Roll Up Doors are one of the most common entry and exit point option in a warehouse facility. They can be either Manual or Motorized.

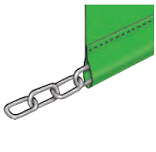

Manual Roll Up Doors has two types. Spring Loaded which works like a venetian blind where you can pull the door down and let the door itself coil up for a full opening. Chan Hoist on the other site works like metal roll up doors where you pull one side of the chain to open and the other side to close.

To allow rapid movement in and out to the curtain wall zone, Motorized Roll Up Doors is a great option. It has variety of speed, frequency, material, sizes and accessories to fit the needs of your warehouse.

Strip Doors

Strip Doors are clear PVC strips that are used to block off openings and gaps. These overlapping strip curtains divide the room while still making it easy to get in and out of the area. Not only that, but they also save energy because they keep cool or warm air inside.

Because they are clear, accidents happen less often, keeping your workers safe from any that could happen because they can't see. It also makes the area less noisy, both inside and outside. This makes the work area more productive because other workers will not get distracted from loud machineries.

Swinging Doors

A free-standing swinging door provides easy access from one side of the curtain wall to the other. This type of heavy duty door is also called an impact door. It can handle a lot of abuse from carts, fork lifts, and heavy foot traffic.

Like kitchen doors in a restaurant, the doors can swing on both sides and are made to be opened by impact.

Swining Doors are a great choice for places where there needs to be a lot of movement but not a lot of infiltration. This door can be made thermal, visual, sound, environmental or secure.

Summary

| Category | Flexibility | Installation Time | Cost | Durability | Best Applications |

|---|---|---|---|---|---|

| Vinyl Curtain Walls | Very High | Very Short | Low | Moderate | Temporary partitions, dust/light control, or areas requiring frequent adjustments. |

| Freestanding Vinyl Walls | Very High | Very Short | Moderate | Moderate | Flexible zoning without attaching to existing structures. |

| Fabric Curtain Walls | High | Short | Low | Moderate | Temperature or humidity control; lightweight and modular. |

| Industrial Canvas Walls | High | Short | Moderate | High | Heavy-duty applications; noise or abrasion control. |

| Strip Curtains (Standard) | Very High | Very Short | Low | Moderate | High-traffic areas; dust, noise, or temperature separation without limiting movement. |

| Welding Strip Curtains | High | Short | Moderate | High | Welding safety and spark containment. |

| Anti-Static Strip Curtains | High | Short | Moderate | High | Environments requiring static control (e.g., electronics manufacturing). |

| Insulated Curtain Walls | High | Short | Moderate | High | Temperature-controlled zones; energy efficiency. |

| Modular Warehouse Walls | High | Moderate | Moderate | Moderate | Reconfigurable partitions for evolving warehouse needs. |

| Pre-Fabricated Walls | Moderate | Moderate | High | High | Permanent or semi-permanent installations with quick assembly. |

| Stick-Built Walls | Low | Long | High | Very High | Permanent separations with the highest durability. |

| Permanent Warehouse Walls | Low | Long | Very High | Very High | Creating permanent, load-bearing partitions. |

| Mesh Partitioning | High | Short | Moderate | High | Securing or separating areas while maintaining visibility and airflow. |

| Pallet Rack Curtains | High | Short | Low | Moderate | Covering storage racks; protecting goods from dust and debris. |

| Portable Warehouse Dividers | Very High | Very Short | Low | Moderate | Temporary or mobile partitions for flexible work zones. |

| Pipe and Drape Systems | Very High | Very Short | Low | Low | Lightweight temporary enclosures or visual partitions. |

Warehouse walls are very important for making the best use of space, keeping temperatures in check, and keeping employees safe. This blog article talked about 11 flexible wall ideas that can make a facility more productive.

You can choose from simple vinyl curtains that come in standard, freestanding, and mesh styles, or you can choose stronger fabric building stores. Industrial curtains are flexible type of curtain divider and usually used in welding areas or areas where temperature are needs to be regulated. They are reasonably priced and are also a great option when you are looking for durability and sustainability.

If you need a more permanent solution, solid walls or pre-finished walls are something you can consider. Although these are more expensive compared to other options, you can rest assure that they are more sustainable and can definitely last longer.

For temporary dividing needs, there are lots of options for portable dividers with different kinds of cover that you can choose from. These are great for warehouse facilities that changes their layout from t time to time. They are relatively cheaper than other options, but they may not be the long-lasting solution that you are looking for.

With all the options provided, you may be wondering still how you will choose from any of them. There are few factors to consider that will help you narrow down your choices and ultimately come up with the decision. First of all, you need to consider your budget and how much you are willing to spend on the dividers. Also consider your warehouse needs, do you often change your layout? What are the areas you need to cover? Do you need to have insulation? Do you need sound proofing? What about the type of access you need?

By thinking about these items carefully, you should be able to choose the best warehouse divider option for your facility and maximize your space for more productivity.