Grinding Booth Curtain Styles

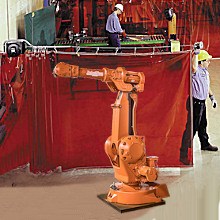

Solid - Welding Curtains

Welding curtains that form a wall or a complete, 4-sided welding booth which can cover a large area.

Designed for high-heat and heavy close proximity welding with hot constant weld slag and sparks.

Used to enclose work areas, these welding rolls zip tie to the welding cell fencing or for static hanging.

Portable - Welding Screens

Retractable welding curtain screens are hand pulled up and are portable. They store in very tight spaces.

Roll up screens for field welding and service trucks. Quick and easy to deploy with no parts to adjust.

Same as the vinyl but in canvas. Designed for heavy close welding with hot weld slag and sparks.

Retractable - Welding Curtains

Retractable welding curtain screens. are hand pulled across the weld cell. Up to 26' in length and freestanding.

Retractable welding curtain screens are hand pulled and portable. Up to 25' in length and freestanding.

Retractable welding curtain screens are hand pulled across the weld cell. Up to 25' in length and freestanding.

Retractable welding curtain screens are hand pulled down in the weld cell. Also swivels out of the way.

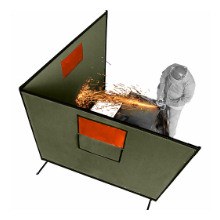

OVERVIEW

AKON’s Grinding Booth Curtains are a great addition for both sanding and grinding applications. The booth curtains provide complete freedom for employees to move effortlessly within the booth. You can perform any type of the manufacturing process with ease and without limitations. The curtains are there to contain dust, sparks, grinding debris and provide proper air circulation when used with proper ventilation systems such as downdrafts.

What Makes Our Grinding Booth Curtains Special?

Grinding Booth Curtain Features:

- Hot-dip galvanizing (HDG) track

- Standard or customized sizes, shapes, and walls

- Modular design or easy set up and expansion

- Heavy duty vinyl, made for industrial applications

- Smooth interior for ease of maintenance

- Clear double polished PVC

- Curtains roll side-to-side for complete access

- NFPA fire retardant, CFM fire retardant

- Finished edges for clean crisp appearance

- Double or triple hems used where needed for longevity

Grinding Booth Curtain Benefits:

- The track has maintenance-free longevity for decades

- Quick and easy installation process

- High energy-efficiency

- Recirculating clean air and dust control processes

- CFM and NFPA-701 flame retardant certifications

- Less expensive than rigid walls and permanent structures

- You can quickly and easily take down the curtains or re-purpose them in other areas of the facility

- Divide the facility into multiple work areas depending on their operations.

- Greatly improve worker safety and comfort

- Easy to clean with slick surface of Vinyl

- Contain welding, over-spray, sparks, and other debris

- Lifetime warranty on all hardware and 5 year warranty on curtains

- Also ideal for: work cells, welding stations, production segmentation, batch mixing, powder coating, wash bays, painting booths, privacy dividers, etc.

Create Your Own Custom Grinding Booth Curtain

Custom Made Per Application

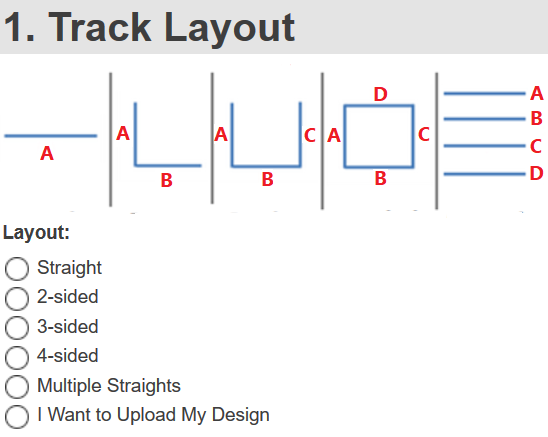

The grinding booth curtains are custom made to suit your application. As the picture to the left shows, you are free to choose a specific track layout. You can have any width you need and up to 15′ in height for free standing and 40' for top down support hardware styles. There are two components to the setup which includes the industrial curtains and the hardware.

The curtains also come in many different colors and several different materials depending on your needs. You can combine static curtains with operable side-to-side curtains and strip curtains with solid curtains.

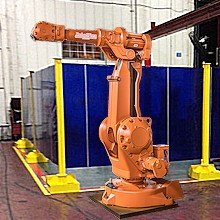

Design The Perfect Booth

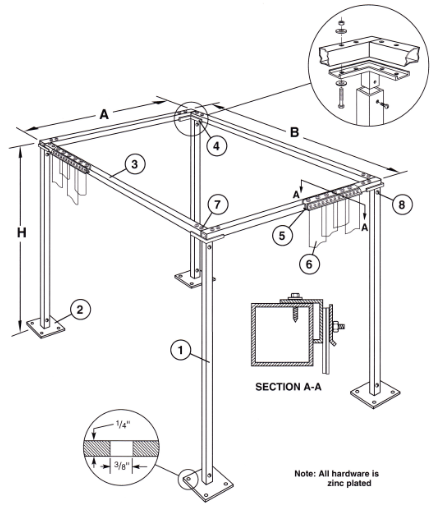

Grinding booths are usually useful in applications where source capture is not practical. Booths can easily fit anywhere on the facility floor. With the addition of special mounting hardware, the booths will barely take any space at all. You have a rich choice of curtain accessories and types to go with. Also worth mentioning, all hardware is zinc plated.

Choose Strip or Solid Walls

Strip Curtains

Strip Curtain Hardware

In this setup solid PVC strip curtains are bolted to the frame. The strips allow people and product to move into and out of the enclosure quickly at almost any location. With this set up there is no need to pull a curtain back to allow access which will in turn increase efficiency for high traffic applications. The strips are clear for a line of sight and can easily be changed out if they get damaged or worn out.

Solid Curtains

Solid Curtain Hardware

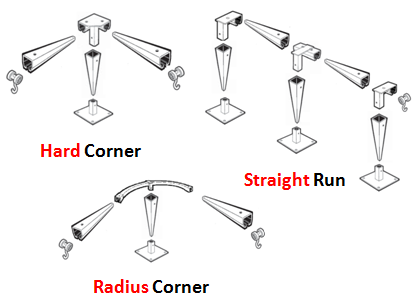

Utilizing most of the same hardware as static hardware, the rolling curtain hardware allows for side-to-side movement of the curtain walls. These Industrial Free Standing Curtains roll on curtain hooks and can have hard corners, radius corners or no corners in case of a single sided setup. The rolling curtain track is slightly offset of the vertical uprights so that the curtain can move freely around the enclosures with no limitations.

Optional Ceilings

Ceilings Curtains

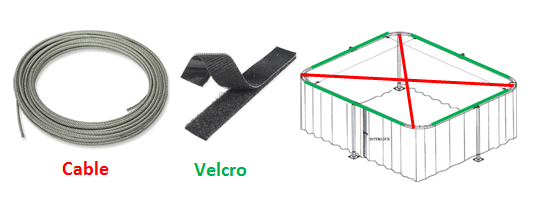

If your application requires a ceiling Akon can provide that as well. The ceilings are a 14mil or 20mil clear Vinyl that drapes over the top of the enclosure. The clear material allows light into the free-standing enclosure while containing or keeping out dust and debris. The ceilings are held up with aircraft cable (shown in red below and supplied by the customer) which spans across the top hardware and then Velcro (shown in green below) attaches to the Vinyl to the frame.