Standard Curtain Track

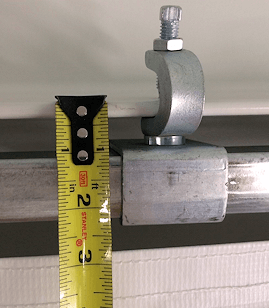

What is the spacing from the bottom of the track to the top of the curtain?

Standard curtains have approximately 0.50″ to 0.75″ of a gap from the bottom of the track to the top of the curtain. This spacing may vary depending on the type of curtain and the production process.

Can the hardware be painted?

Akon does not paint the hardware. The curtain track hardware is made from raw galvanized steel, which is corrosion-resistant and does not require painting. However, if you prefer a different finish, you can spray paint it using a metal-compatible paint.

What are the dimensions of the track?

The curtain track has a width of X inches and a height of Y inches. It is designed to work with our standard 1-inch nylon roller hook.

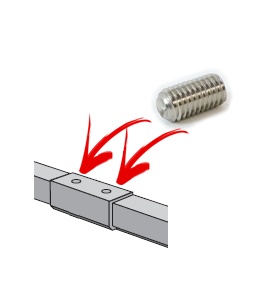

What's a "splice" and what is a "connector"?

A Splice connects two pieces of track together and supports it. A Connector only holds the track up. Akon has standardized on using only splices since they are multi-function. Below is a splice that is both connecting the track together and holding it up. You can slide the splice anywhere on the track not just at junctions.

What holds the track sections together?

Set screws join the tracks together. These ship with your order. If you need to purchase them locally they are Allen Nuts - 3/8"-24 - 3/8" long - half dog set screw (Self Lock Cup Point Set Screw)

Can I simply drill straight through the track and into the ceiling / structure?

Yes. This is called a flush mount install and is very common. Simply drill through the middle of the track and use a small wood screw, bolt, Tek screw...ect into your structure. Space the holes about every 3-5'.

What is the USDA Curtain Track?

In wash down applications where there is open food or a need for a clean environment then the USDA curtain track is ideal. More info on USDA curtains and tracks

What are the different curtain mounting options?

Click here to view our different hardware mounting options for the curtains.

Will the curtain track rust?

The track is Hot-dip galvanizing (HDG) which is often used to protect steel from corrosion in some of the harshest environments imaginable, yet it provides maintenance-free longevity for decades. The corrosion resistance of hot-dip galvanizing varies according to its surroundings but generally corrodes at a rate of 1/30 of bare steel in the same environment.

How hard is it to install the industrial curtain track?

It is very easy. All of the components simply fit into each other and connect with set screws. The installation is very intuitive. If you have any difficulty simply call or email us and we will walk you through the process.

Are there installation directions?

Yes there are step by step installation directions below.

Should I deduct curtain height to accommodate the curtain track?

When we quote you a curtain and track we generally deduct 3″ from the height of your requested curtain to accommodate for the curtain track. If we do this it is specifically called out on your quote. This 3" deduction keeps your curtain just off of the floor.

Do you provide any screws or fasteners to attach the track to my structure?

We actually do not provide fasteners. There are many different structures customers attach to so we let the customers source those. You can buy that at your local hardware store.

Can the track be cut to size as required on site?

Yes the track is made to be field cut on site using a hack saw or sawzall.

What is the track material?

You can choose from standard galvanized track (Hot-dip galvanizing (HDG)) or optional stainless steel track. Stainless Steel is available but will cost about three times the galvanized and has a longer 2-3 week lead time.

How close together do I need the track supports?

The track should be supported approximately every 5' with a track support. The farther apart the track supports, the greater the deflection. If you have a relatively light weight curtain then you could space the supports out to about 8' apart.

What is the difference between a hard corner and two separate curtains that meet at the end?

A hard corner is a fixed connection where two curtains meet at a 90-degree angle, they are esentially the same thing. The two curtains meet at a corner but do not connect

Curtain Hooks

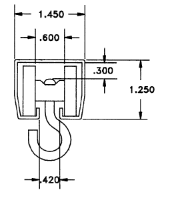

Are there different hook styles to choose from?

Yes there are different roller hooks to choose from. The standard hook we quote unless specified is a nylon roller wheel with a 1" hook with the part number 16NR1. There is also a steel version of that roller with the part number 16SR1. If you need a special roller hook you can view them here.

Can the trolleys be used to hold up something besides a curtain?

Yes. It is very common for our customers to use the tracks to hold up sport nets, cables, panels.. and many other products. Some customers use our industrial track as an industrial trolley to move parts around the shop floor.

Why would you want a steel wheel vs a nylon wheel?

For very tall curtains over 30' they will roll easier than they nylon wheels. Steel wheels are also louder as they are steel rolling inside a steel track. In addition to the noise they are also more expensive. Steel rollers use ball bearings for a smooth rolling motion and added load rating.

Can the curtains overlap each other?

Yes. We can provide an overlap trolley which allows the curtain to overlap another curtain on the same track. This is ideal for wash bays or where a good seal between two curtains is required. This could be used in place of actually connecting two curtains together using. Great for high frequency traffic through the curtain.

When would you need a pull rope trolley?

A trolley is recommended for curtains 13 feet or taller. They are designed to eliminate a lot of the tugging or pulling on curtain when opening or closing. The trolley attaches to the leading grommet and a cord with a handle is then dropped down to a comfortable height. The user then uses the cord to walk the curtain open and close it.

How many hangers are needed for my curtain?

As an industry standard for industrial curtains there is one grommet per linear foot at the top of the curtain. So when we quote your curtain track we quote 1 roller hook per linear foot of track. So if you ask for 50' of curtain track we will quote 50 roller hooks. You can ask for more or less based on your application.

How much weight are the curtain hooks rated for?

(2) Wheel Nylon – 40lbs each (Standard)

(2) Wheel Steel – 75lbs each

(4) Wheel Steel – 125lbs each

Radius Corners

Can the curtain roll around the radius corner?

Yes. Almost any configuration is possible with the use of the 90 degree radius corners. These 24” radius corners allow the curtain to roll from one side to the other side with ease.

Can we have a custom radius corner made?

At this time we do not provide custom made radius corners due to the high cost of tooling and the long lead times.

Are there splice connectors welded to the end of the radius corners?

Yes there are. These connect to the straight tracks.

Does the radius corner make the track longer?

Yes. The standard 90 degree radius corner has a 24" radius so if you for example had 10' of straight track then added the radius corner you would have 12' tip to tip.

Media

An overview of the different hardware mounting methods

Common Questions

What is the maximum weight capacity of your trolley track?

Our overhead trolley track has a maximum capacity of 125 lbs per linear foot. The load capacity also depends on the type of roller hook used:

- 40 lbs per nylon roller hook

- 70 lbs per steel roller hook

- 125 lbs per 4-wheel steel roller hook

Can this track system be used for applications other than curtains?

Yes! While designed for industrial curtains, this track system can also be used as an overhead trolley for lightweight loads, sliding privacy partitions, and even certain storage applications.

Do I need to buy additional roller hooks?

Each system comes with a standard set of roller hooks, but additional hooks can be purchased separately if needed. More rollers allow for greater curtain support and smoother operation.

Can I connect multiple track sections together?

Yes! Our track sections can be joined using track splices to create longer continuous runs. Proper alignment is essential to ensure smooth roller operation.

What is the difference between nylon and steel roller hooks?

Nylon rollers: Quieter, smoother operation, and resistant to rust. Best for light to medium-duty applications.

Steel rollers: Heavy-duty, designed for high-weight capacity, and longer-lasting. Ideal for tough industrial environments.

Do you offer mounting hardware for high ceilings?

Yes! We provide threaded rod mounting kits that allow you to suspend the track from high ceilings, making it ideal for warehouses, production areas, and industrial workspaces.

What if I need to move or reconfigure the track later?

The track system is designed for flexibility. You can easily disassemble and relocate the track, add extra sections, or change the mounting style if needed.

Can I install the track system myself, or do I need a professional?

Many customers install the system themselves with basic tools (drill, screws, saw for custom lengths). However, for large-scale or complex installations, professional assistance may be beneficial.

Can I use this track for a soundproofing or noise control curtain?

Yes, the track can support heavy-duty acoustic curtains to reduce noise levels in manufacturing plants, music studios, and offices. Make sure the roller hooks can support the curtain weight.