Curtain and Dividing Systems for Warehouse

Dividing a large warehouse can be a very tough job to do considering production and expense. But with the AKON modular wall dividing system, dividing a large industrial plant will take less time and effort. AKON can give you warehouse dividing options that are very inexpensive and very quick to implement.

Most times companies decide to share a facility for a different production process. This sharing goes a long way and can cause damage to individuals, products and the environment. It might also lead to certain damage which will affect the growth of the business. There is no way you can avoid the noise and contamination from both production process.

Complete Containment Solution

Any Layout For Your Needs

How to Effectively Warehouse Space

Advantages of Modular Walls

Our modular wall provides clean production process separation in a facility, at a minimal cost with little or no mess. Knowing how to divide warehouse space is an advantage that can save you money. Our modular wall can be uninstalled in no time and assembled in a new facility just as quick. This is a huge cost savings over rigid walls. The following are what AKON modular walls can provide:

- Dust and fiber debris

- Industrial fallout

- Humidity control

- Product processing fumes

- Less Noise

- Air Temperature and quality

- Lighting

- Individual Access

- Separates working environments in the same vicinity

Create New Warehouse Space

Effective Warehouse Dividing Walls and Flexible Insulated Curtains

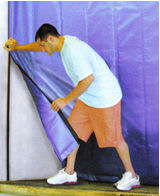

With proper installation most facilities can use the AKON industrial curtain dividers which totally separate production space. Visual floor space separation is best for facility division. The in-plant environmental floor space division involves separating warehouse floor space by eradicating all possible means of allowing air, dust, light and most importantly noise from one production space to the other. AKON, over the years, has developed a very efficient, fast and most of all economical way of separating the warehouse. This warehouse partitioning system uses our standard curtains with field cuts around obstructions for a perfect fit.

Using a flexible insulated or non insulated industrial curtain, we can be divide your warehouse into different zones in no time. These dividing walls are installed at a very economical price within a short period of time compared to the traditional stud partition wall construction.

Material Options

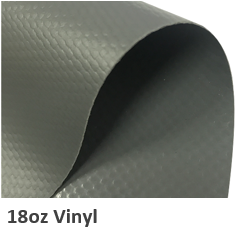

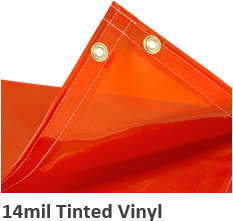

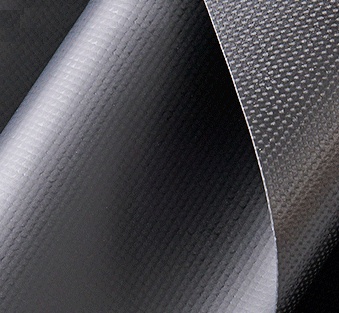

Opaque Vinyl

Industrial grade 18oz opaque vinyl ideal for moderate temperature control and blocking line of sight. $$

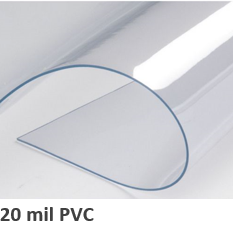

Clear Vinyl

Industrial grade 30mil clear vinyl ideal for moderate temperature control and allowing a line of sight. $$

Insulated Vinyl

Industrial R3 1/2" thick material with 18oz vinyl skins ideal for heavy temperature control and blocking the line of sight. $$

Entry Points

Entry Options

If you are using larger static position curtain walls that will not roll side to side then using entry points is ideal. These openings allow people and product into the curtained area quickly and with little effort. The most common entry and exits are strip curtains, swinging doors or powered roll up doors. Strip doors being the most common and economical. Each version features a freestanding frame that anchors into the floor and seals to the curtain wall.

Contain Construction Dust

Temporary Demising Curtain Wall

If you have construction taking place at your warehouse then the warehouse dividing curtains can serve as a temporary demising wall. The curtain material as discussed above is relatively inexpensive and forms a perfect barrier dust control during the construction process.

- Demising curtains are constructed to seal tight to the floor, ceiling and walls to control dust.

- Can be custom fabricated to sync with the pitch of the roof and give a befitting look.

- Installing process is fast and easy.

- Demising Curtain Walls have the features of adding access doors, windows as needed at any part of the wall.

- Should in-case there is a need for a large door opening or roll up doors for forklifts and other product transportation devices to pass through, a door can be added anywhere to give such access.

Make Temporary Warehouse Spaces

Create Temporary Warehouse Space

In a standard facility, environmental conditions are contained in the chunk given to a particular production process by a warehouse dividing walls. Temporal and permanent walls can be fixed in facilities although the temporal wall is easily installed and can be adjusted anytime. The permanent wall is time-consuming, more expensive and would stall production till is fixed and ready. Unlike the permanent wall, it is cost-effective, requires little time to install and would not stop the production process but reduce contamination drastically.

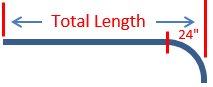

Curtain Track

- 16 gauge galvanized steel tracks

- Nylon roller hooks for easy opening

- 6 mounting styles to connect to various structures

- Free standing hardware for up to 20' in height

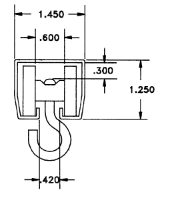

Static Mount Hardware

- Aluminum Angle - Use with self tapping Tek screws to pinch curtain to angle.

- Grommets Only - You can then use many DIY methods to hang the curtains.

- Beam Clamps - Clamps onto the flange of beams, joists and purlins.