Partitions for Distribution Centers

What You Will Learn

Maximizing space in a distribution center is about smart organization rather than only about stacking your products. Choosing the correct partitions can change the layout of your facility and create zones for security, operations, and storage. The correct partitioning solution can make all the difference whether your needs are for workstation creation, traffic flow improvement, or high value inventory segmentation.

Let's look into the best solutions for dividing out your distribution center space.

More Than Walls: How Partitioning Boosts Productivity

Temperature Zoning

Create temperature zones to store goods at various temperatures or to make the workplace more comfortable for employees.

Humidity Control

Control humidity inside your facilities for food goods or improved production techniques with efficiency.

Separate Tenants

Lease or zone your warehouse to tenants whose various operations call for separate areas.

Control Noise

Soundproof or insulated dividers help to contain noise from forklifts and loud machines, creating a more peaceful workplace.

Control Dust

Protect your employees from any diseases caused by inhalation of airborne dust through warehouse divider walls.

Personalized for Your Operations

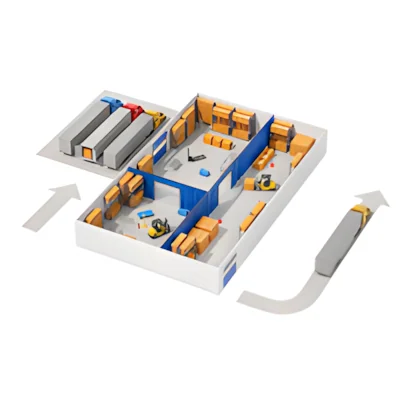

Choosing the Right Fit for Your Facility

Distribution center partitions

Conventional solid walls could restrict your capacity to maximize your area as the business grows. Modern distribution centers must be adaptable to new products, procedures, and tenants fast.

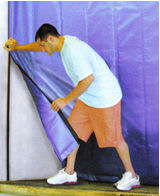

A flexible approach to separate your building is with modular walls. As your demands change, their modular architecture lets you readily install, rearrange, relocate, or delete them. Modular walls give a strong and flexible answer whether your needs are for separate work zones, noise control, or organization enhancement.

Key Benefits

Distribution facility dividers offer many practical advantages for your facility. They help cut down on heating and cooling costs while letting you close off extra space until you need it later. These vinyl dividers cost much less than building permanent walls. They also keep dust, paint spray, and smoke from spreading throughout your warehouse.

Workers benefit, too, since divider curtains help maintain comfortable humidity levels and temperatures, which is especially important in cold storage areas.

The flame-retardant fabric stops fires caused by sparks, which is very important for safety at work. These curtains are very flexible because they can be made in any size, so they fit perfectly in any type of space. You have flexible installation options because of the different mounting options available.

They can also keep rooms up to 40 degrees cooler or warmer, which is another great thing about them. To control the flow of air in buildings that have trouble moving it, mesh screens can be added.

The flexible design means that the distribution center can be changed as needs change in the future. Floor anchoring systems keep things stable in areas with a lot of foot traffic, and Velcro connections between curtain pieces make sure there is a continuous, safe barrier all the way through the building.

Overall, these simple solutions make your distribution center more efficient, cleaner, and more comfortable for everyone working there.

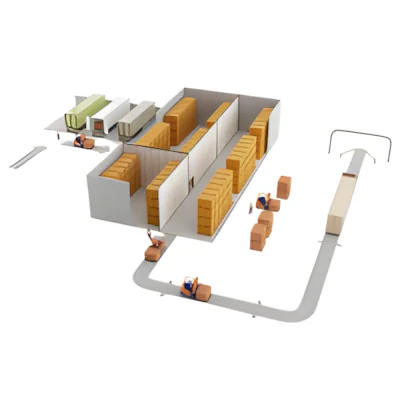

Insulated Walls For Distribution Centers

Insulated Distribution Partitions

Looking to split up your warehouse without breaking the bank on permanent walls? Insulated warehouse curtains might be just what you need.

These tough, flexible dividers create separate zones in your distribution center without the headache of construction. These aren't your average curtains. The insulated material can maintain up to a 40-degree temperature difference between areas - that's huge for your energy bills.

It can be customized to fit any space, no matter how odd-shaped your warehouse might be.

Key Benefits

Insulated distribution divider curtains offer a good way to insulate or separate temperature zones within your distribution center.

These curtains come in 5-foot-width panels that Velcro firmly fastens together. R-values range from R3 to R15, therefore providing diverse degrees of thermal resistance to fit various temperature control requirements.

Apart from its insulating features, these divider curtains have an inside double-batting antibacterial core that combines temperature control with further hygienic advantages. They provide improved climate control and all the usual features of non-insulated dividers as well.

Together with refrigeration and HVAC systems of a facility, thermal warehouse curtains help to control humidity levels and temperature. These curtains provide effective operation and energy savings by choosing the suitable R-value, therefore helping to meet the intended environmental conditions.

These curtains prevent dust, paint overspray, and factory smoke within, therefore improving air quality in addition to helping with space management.

Whether your facility requires storage that stays at a specific temperature, defined work zones, or a more flexible plan, these curtains provide the protection and flexibility it requires.

Noise Reduction

Noise-Reducing Partitions with Akon Sound Curtains

Akon sound-reducing curtains offer an effective solution for controlling noise pollution in bustling distribution centers. These specialized acoustic barriers absorb and block sound waves, significantly reducing noise transfer between different operational zones. Installation is quick and flexible, allowing warehouse managers to create quiet work areas without permanent construction. The heavy-duty vinyl and sound-dampening materials withstand industrial environments while maintaining excellent acoustic properties. For distribution centers with noisy equipment, loading docks, or packaging stations, Akon curtains create a more comfortable working environment, improving employee focus and reducing noise-related stress and fatigue.

Dust Control

Dust control partitions for distribution hubs

Akon curtains provide essential dust containment solutions for distribution hubs where particulate control is critical. These industrial-grade partitions create effective barriers that prevent dust migration between different operational zones. The tightly woven, durable material captures airborne particles while still allowing for workflow flexibility. Distribution centers benefit from Akon's customizable installation options—whether permanently mounted or on sliding tracks for temporary deployment during high-dust activities. These partitions help maintain cleaner air quality, protect sensitive inventory from contamination, reduce cleaning requirements, and support compliance with occupational health standards. For distribution hubs handling paper, cardboard, food products, or other dust-generating materials, Akon curtains offer a practical and cost-effective containment strategy.

Air Ventilation

Vinyl Mesh Curtain Walls for Visible Separation

Akon vinyl mesh curtains deliver the perfect balance of separation and visibility for distribution hubs. These specialized partitions create defined zones while maintaining crucial sightlines for operational awareness and safety. The breathable mesh design allows for natural airflow, preventing heat buildup and promoting ventilation without compromising boundary integrity. Distribution centers particularly value these semi-transparent barriers for areas requiring visual supervision while controlling access. The durable vinyl construction withstands industrial environments while remaining lightweight and easy to reconfigure. Perfect for creating flexible workspaces, designating pedestrian paths from forklift zones, or establishing quality control areas, these mesh partitions enhance organization without the closed-off feeling of solid barriers—improving both efficiency and communication throughout the facility.

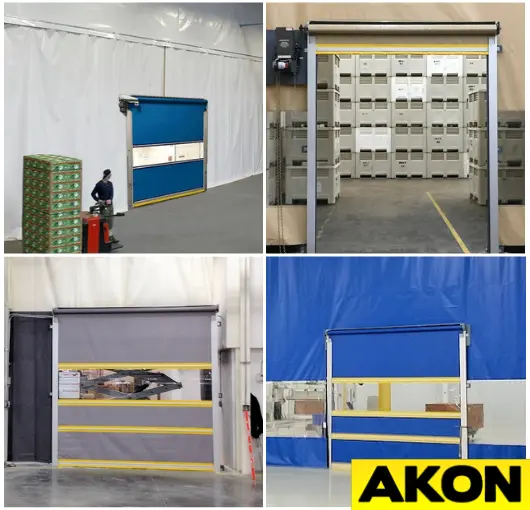

Entry and Exit Solutions

Roll Up Doors are one of the most common entry and exit point option in a distribution facility. They can be either Manual or Motorized.

Manual Roll Up Doors has two types. Spring Loaded which works like a venetian blind where you can pull the door down and let the door itself coil up for a full opening. Chan Hoist on the other site works like metal roll up doors where you pull one side of the chain to open and the other side to close.

To allow rapid movement in and out to the curtain wall zone, Motorized Roll Up Doors is a great option. It has variety of speed, frequency, material, sizes and accessories to fit the needs of your warehouse.

A free-standing swinging door provides easy access from one side of the curtain wall to the other. This type of heavy duty door is also called an impact door. It can handle a lot of abuse from carts, fork lifts, and heavy foot traffic.

Like kitchen doors in a restaurant, the doors can swing on both sides and are made to be opened by impact.

Swining Doors are a great choice for places where there needs to be a lot of movement but not a lot of infiltration. This door can be made thermal, visual, sound, environmental or secure.

Frequently Asked Questions

Frequently Asked Questions: Industrial Partitions for Distribution Centers

- Vinyl/PVC: Economical, easy to clean, and available in various colors and thicknesses

- Mesh: Provides visibility and airflow while maintaining separation

- Fabric: Offers sound absorption properties and aesthetic appeal

- Curtain systems: Typically 1-2 days for standard installations

- Custom solutions: May require 5-10 days

- Curtain systems: Our track-mounted curtains can be slid open/closed or completely relocated

- Flexible mounting options: Allow for adjustments to accommodate changing needs

- Vinyl curtains: Regular cleaning with mild soap and water; inspect for tears or damage

- Track systems: Occasional lubrication and clearing of debris

- Mesh partitions: Check for tension and clean dust accumulation

- Material safety certifications: All materials are tested for chemical emissions and safety

- Industry compliance: Our products are designed to meet OSHA workplace safety guidelines

- Durability testing: Products undergo rigorous testing for longevity in industrial environments

- Quality assurance: Manufactured under strict quality control processes

- Insulated options: Available for maintaining temperature differentials up to 20°F

- Specialized seals: Floor sweeps and side seals to minimize air exchange

- Thermal curtains: Specific solutions for freezer/cooler applications

- Temperature control applications: 8-14 months through energy savings

- Dust/contaminant control: 10-16 months through reduced cleaning and maintenance costs

- Space optimization: 6-12 months through improved space utilization

- Climate-controlled areas: 12-18 months through reduced HVAC costs

- Color matching: We can match your corporate colors (PMS matching available)

- Logo printing: High-quality logo application on vinyl curtains

- Zone identification: Color coding for different areas or departments

- Safety messaging: Custom safety instructions or warnings

- Zoning: Allowing targeted heating/cooling of only occupied or necessary areas

- Air containment: Reducing the mixing of conditioned and unconditioned air

- Load reduction: Decreasing the square footage that needs to be conditioned

- Airflow management: Controlling where air flows within your facility

- Acoustic curtains: Single or multi-layer options with sound dampening properties

- Fabric partitions: Materials designed to absorb sound waves

- Strategic placement: Expert consultation on optimal positioning for noise reduction

Photo Gallery

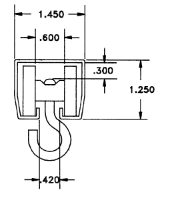

Curtain Track

- 16 gauge galvanized steel tracks

- Nylon roller hooks for easy opening

- 6 mounting styles to connect to various structures

- Free standing hardware for up to 20' in height

Static Mount Hardware

- Aluminum Angle - Use with self tapping Tek screws to pinch curtain to angle.

- Grommets Only - You can then use many DIY methods to hang the curtains.

- Beam Clamps - Clamps onto the flange of beams, joists and purlins.