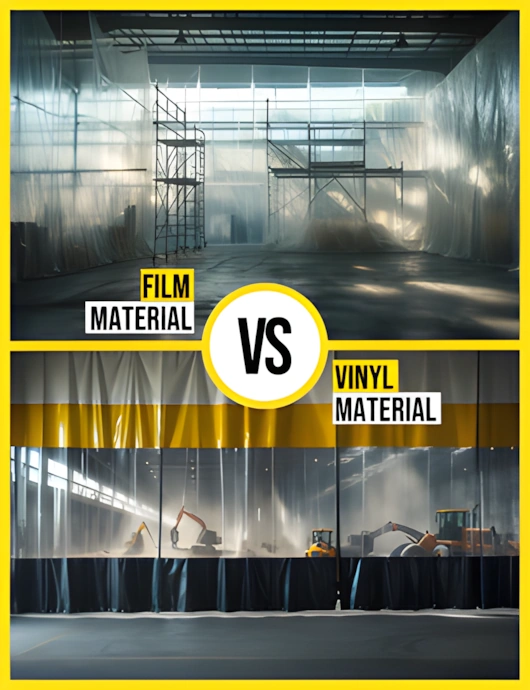

Choosing Between Vinyl and Film: A Matter of Project Timeline

When planning temporary construction barriers, project duration should be a primary factor in your material selection. For projects spanning multiple months, 13oz vinyl material represents the optimal choice, while shorter timeframes may benefit from film alternatives.

Overview

Pros and Cons | 13oz Vinyl

Using 13oz Vinyl for Temporary Construction Walls

Advantages

- Superior durability with resistance to tears, punctures, and impacts in high-traffic construction environments

- Maintains structural integrity throughout extended projects without sagging or deterioration

- Professional appearance with smooth, wrinkle-resistant surface that creates positive client impressions

- Cost-effective for long-term projects (3+ months) due to eliminated replacement costs and reduced labor

- Enhanced safety and containment properties with better dust/debris control and consistent barrier performance

Disadvantages

- Higher initial investment cost compared to lightweight film alternatives

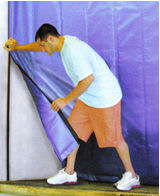

- More challenging to install due to heavier weight requiring stronger mounting hardware

- Less flexibility for rapid reconfigurations when project layouts change frequently

- Potentially excessive for very short-term projects (under 1-2 months) where durability benefits aren't realized

- More storage space required between projects if planning to reuse materials

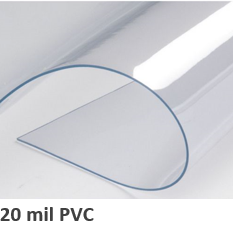

Pros and Cons | Film

Using Film For Temporary Construction Walls

Advantages

- Significantly lower upfront cost, making it economical for short-term projects

- Lightweight and easier to handle during initial installation

- Quicker to set up with simpler mounting requirements

- More flexible for frequent layout changes or rapid reconfigurations

- Requires less storage space when not in use

Disadvantages

- Highly susceptible to tears, punctures, and damage from normal construction activity

- Poor longevity, often requiring multiple replacements during medium to long-term projects

- Unprofessional appearance with tendency to wrinkle, sag, and discolor over time

- Higher total cost for projects lasting more than 2-3 months due to replacement needs

- Less effective at containing dust, debris, and noise with compromised barrier integrity

So Which One Is Best?

Long-Term Projects: The Vinyl Advantage

Construction projects extending beyond a few months benefit significantly from investing in 13oz vinyl barriers. The initial higher cost quickly becomes justified as the material's durability eliminates frequent replacements. Over extended periods, vinyl walls maintain structural integrity despite constant exposure to construction hazards, temperature fluctuations, and daily wear.

The math becomes clear when calculating total expenses: a single vinyl installation that lasts 6+ months versus multiple film replacements, additional labor costs, and potential project delays. For longer projects, vinyl's professional appearance also maintains site aesthetics throughout the duration, creating a consistently positive impression with clients and stakeholders.

Short-Term Projects: When Film Makes Sense

For projects lasting only a few weeks, lightweight film barriers can be a cost-effective solution. When exposure time is limited, the risk of tears and damage decreases substantially. Short-term construction doesn't subject materials to seasonal changes or extended stress periods, making film's lower upfront cost appealing. Quick renovation projects, weekend work, or emergency repairs may not justify premium materials when the barriers will be removed before they've had time to deteriorate.

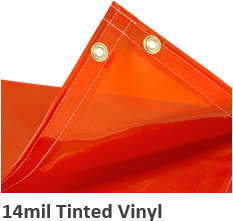

Branding Opportunity: Why Vinyl Stands Out

Personalized branding is one reason why vinyl curtain walls are better than thin film. You can use the vinyl curtain to help market and brand your company by adding your name to it. A branded site not only looks more professional, but it also gets more attention, which builds trust with customers and brings in new ones. Vinyl can be recycled and lasts a long time, so your investment in marking will last for many projects. Vinyl is better than thin film for making a portable wall that keeps people in and makes your business look better.

Reusable and Cost-Effective: Vinyl’s Long-Term Advantage

Vinyl curtain walls are made of strong materials that last a long time making it more cost-effective choice in the long run. Vinyl can be taken off, kept, and put back on as needed, while thin film has to be thrown away after just one use, which leads to more waste and higher costs. This not only lowers the cost of materials but also has less of an effect on the earth. Contractors who want a temporary wall option that will last longer and be more environmentally friendly should buy vinyl instead of disposable thin film barriers.

The Decision Point

The pivotal question becomes: At what project duration does vinyl become the more economical choice? Most contractors find that the crossover point occurs around the 2-3 month mark, where replacement costs for film begin to exceed vinyl's initial investment. Also, a strong factor in choosing a material is aesthetics: will there be customers or guests in the area? If so, then many contractors lean towards the vinyl.

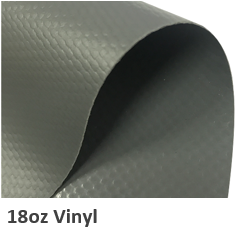

| Factor | 13oz Vinyl | Film |

|---|---|---|

| Durability | ⭐⭐⭐⭐⭐ High resistance to tears, punctures, and impacts; suitable for high-traffic areas. | ⭐⭐ Lower resistance; more prone to damage in demanding environments. |

| Longevity | ⭐⭐⭐⭐⭐ Can last years with proper care, making it a great long-term investment. | ⭐ Best for short-term use; may degrade or tear quickly with extended exposure. |

| Project Duration | Ideal for long-term projects (3+ months) due to sustained structural integrity. | Suitable for short-term projects (under 1-2 months) where frequent changes are anticipated. |

| Cost | 💲💲💲 Higher initial investment but cost-effective over long durations by reducing replacement needs. | 💲 Lower upfront cost, making it economical for short-term applications. |

| Install Costs | Heavier material requiring robust mounting hardware; more challenging to install. | Lightweight and easier to handle; quicker setup with simpler mounting requirements. |

| Flexibility | Less adaptable to rapid reconfigurations; better for static layouts. | Highly flexible; ideal for projects requiring frequent layout changes. |

| Visuals | Smooth, wrinkle-resistant surface offering a professional look. | May appear less polished; suitable when aesthetics are less critical. |

| Dust Control | Provides better dust and debris control; maintains consistent barrier performance. | Offers basic containment; may require more maintenance to ensure effectiveness. |

| Custom Printed Logos | ✅ Can be customized with logos, branding, or safety messages. | ❌ Not suitable for printing; limited customization options. |

Frequently Asked Questions - Temporary Construction Wall Materials

Film Material

13oz Vinyl Material

Comparison Questions

Ordering Information

Photo Gallery

Curtain Track

- 16 gauge galvanized steel tracks

- Nylon roller hooks for easy opening

- 6 mounting styles to connect to various structures

- Free standing hardware for up to 20' in height

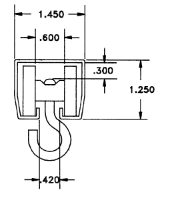

Static Mount Hardware

- Aluminum Angle - Use with self tapping Tek screws to pinch curtain to angle.

- Grommets Only - You can then use many DIY methods to hang the curtains.

- Beam Clamps - Clamps onto the flange of beams, joists and purlins.