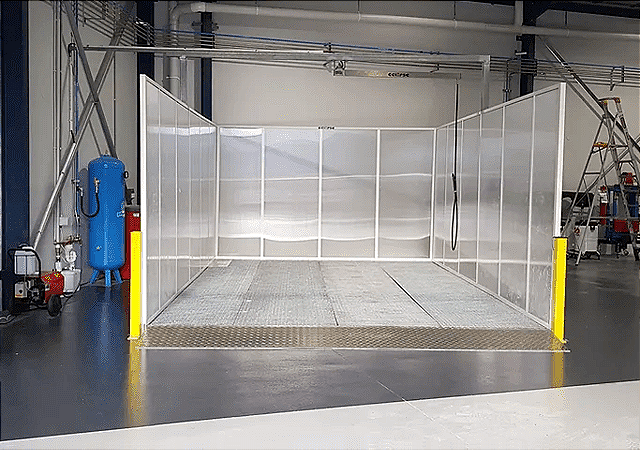

#1 - Self-Contained Wash Bays | Wash Pads

The self-contained wash bays are an ideal for multi-story car parks. Combined with amazing water treatment systems, the wash bays will prevent any spills. Wash racks and wash water recovery systems are great for preventing onsite contamination. These self contained wash bays feature a low profile for vehicle access along with solids removal and and water filtration. Safely remove wash water, mud and debris and follow regulations.

These wash bays are considered a wash bay with a capture system. They feature a built-in or high-quality portable water recovery system that automatically collects your wash water for filtration, conditioning and reuse within the system, or safe discharge to your sewer. Why you would want this system. This system is ideal if you need a wash system off site or onsite that also captures all of the wash down water and debris.

Considerations

PROS

- Comes with chemical storage

- The wash bays are portable

- Can harvest rainwater

- Protects the environment from waste water

- Meet OSHA guidelines if you are in a sensitive area

CONS

- This type of wash bays is an expensive solution

- While portable, the wash bay weighs a lot and requires a complete deconstruction before moving it

Cost and Installation

Materials: $10 000-$30,000 for the entire kit

Installation: $2,000 for installation team

Duration of Install: 5-14 Hours

Helpful Video

#2 - Transportable Equipment Rooms

While this is not a wash bay but rather the equipment that you need to make the wash bay. The transportable equipment rooms (TERs) are commonly used at car washes, military bases, construction sites, and more. The room is placed adjacent to the wash pad. It contains full water circulation, high volume desilting and high pressure cleaning systems. If you are at a remote location this equipment can be shipped as a self contained to hassle solution for your washing equipment needs.

They are ideal for installing scrubbing and recycling equipment on-site without incurring construction costs, delays or permanent structures. These systems can be configured for a variety of applications and put into operation within days.

Considerations

PROS

- Ideal for remote wash down equipment needs

- Made for heavy-duty industrial operations

- Complete closed-loop water recycling system

- Easy to ship and pickup once done

- Comes with optional water recycling, demucking, and pressure washing systems

- Can be trucked from jobsite to jobsite as needed

CONS

- Not ideal for locations where portability is not required

Cost and Installation

Materials: $15,000-35,000

Installation: $1,000 for installation crew

Duration of Install: 2-8 Hours

Helpful Video

#3 - Wash Bay Curtains | Hanging

These vinyl wash bay curtains will contain over-spray from power-washing with easy. Wash bay curtains, also know as wash stall curtains, are common in applications where power washing is taking place to clean equipment, cars, trucks, or products. The curtains are hand pulled around the equipment being washed to contain the spray. The curtain track that holds the curtains is made from galvanized steel. These curtains are the standard for autobody shops and many car washes around the country. They are very inexpensive to purchase and install versus fixed steel structures that sit on the floor. When not needed, they roll back into a very small footprint freeing up the wash bay area for other activities.

Considerations

PROS

- Very low prices viruses other styles of wash bays

- The curtains are highly portable and therefore easy to install, remove, store, or repurpose for other applications

- They come with custom sizes, layouts, colors, and more

- Vinyl which is resistant to almost all wash down chemicals

- NFPA 701 & California State Fire Marshall Standards

- Very small footprint when not needed

- Curtains can be replaced at a very low cost if needed

CONS

- Vinyl can fly around in the wind so unless you anchor the bottoms they can flap around

- Very close power washing can rip through the curtains so you should keep them about 5-8' away from the power washing spray.

Cost and Installation

Materials: $500-$4000

Installation: DIY or $600 for a handyman

Duration of Install: 1-8 Hours

Helpful Video

Photo Gallery

#4 - Wash Racks | Built In

Just like the portable wash pads the wash racks can also be closed loop to capture the water and gunk. These units however are built right into your concrete floor making them a permanent installation. The water drains into the floor and goes into the closed loop cleaning system.

Considerations

PROS

- Conserve water and prevent spills

- Meet OSHA guidelines with closed loop system

- Drains right into the floor drain for quick processing

- Made for heavy equipment and light equipment

- Very high end solution for wash bays needing containment

CONS

- One of the most expensive washing solutions

- Expensive installation required

- Floor excavation required and potential permitting

Cost and Installation

Materials: $30,000 - $100,000

Installation: $10,000 - $25,000 for installation crew

Duration of Install: 3-5 Days

Helpful Video

#5 - Portable Wash Down Screens

The vinyl wash bay screens are portable and super useful in tight spaces. They will contain over-spray from washing and prevent chemical spills or storm water runoff. These portable water spray guards will keep the water overspray from areas that you don’t want it. Roll the portable wash down barrier from one area to another quickly to keep water spray contained in the area you want it. Being lightweight and sturdy, the mobile water spray guards are commonly used for industrial wash bays, commercial wash bays and home garage wash bays. The divider screens can form a single separation partition, a two-sided enclosure, three side enclosure, or four sided enclosure along with multiple other configurations. The PVC is also easy to clean with its slick surface.

Considerations

PROS

- The screens are amazing in tight spaces where other wash bay methods cannot be used

- They are lightweight and can easily be carried from one job site to another

- Quick to move into place and quick to remove when not needed

- Clear PVC allows a line of sight through them

- Very inexpensive

CONS

- Not made for very close range power washing as they could blow over

- Great if you only need a few screens but for large coverage they are not practical

Cost and Installation

Materials: Between $150 and $1200

Installation: DIY

Duration of Install: 10min Per Screen

Helpful Video

#6 - USDA Wash Down Curtains

Food processing wash bay enclosures requires high end materials to meet code. These curtains are designed with non-porous PVC materials which eliminate the opportunity for bacteria to grow and contaminate the products. The stainless steel curtain track is also specially designed as to not allow any debris contamination to build up. The combination of unique features in these USDA wash down curtains improves plant sanitation and reduces downtime on the line.

The PVC material also should be Title 21 CFR Approved to meet code in the USA and CFIA Approved for Canada. The mounting hardware is a stainless steel tubular design with rounded corner curtain carriers. This design allows for water and debris to easily roll off the hardware.

Considerations

PROS

- Prevents cross-contamination between equipment

- The curtains easily contain water spills and debris

- Less expensive than panel walls

- Can be taken down and moved unlike panel wash walls

- Vinyl which is resistant to almost all wash down chemicals

- Track can be made into any shape to go around equipment

CONS

- Curtain track requires a stainless steel welding installer

- Curtain track can be repurposed but not quickly

Cost and Installation

Materials: $3,000 to $20,000

Installation: $1,500 to $6,000

Duration of Install: 1-5 Days

Helpful Video

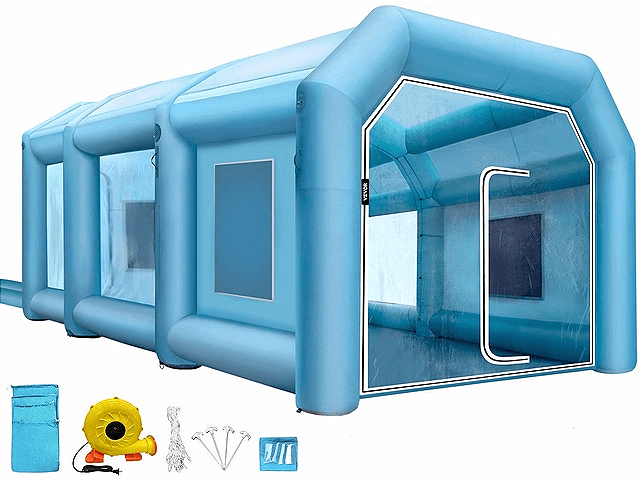

#7 - Inflatable Spray Booth Tents

The inflatable spray booths are dual purpose. They can be used for painting or they can be used as inflatable wash bays to contain overspray. These inflatable booths are usually made from 22oz Vinyl which is the same material a kids bounce house is made of. You simply lay the material out flat on the ground, attach the blower fan, turn it on, and it inflates in about 5-10min. You keep the fan running while in use and when you are done it can be quickly packed up and stored or taken to the next jobsite. They are usable both indoors and outdoors. The booths come with a filtration window system, an inflation blower, and a ventilation blower. There is however no water or debris capture system so any waste water will simply flow out of the inflatable wash booth.

Considerations

PROS

- Great weather resistance and longevity

- Inexpensive considering the size of the enclosure

- Very easy to setup, inflate, take down, and store

- Very easy to reposition elsewhere on the site

- Lightweight at 14 kg without the blowers

CONS

- Prone to ripping of the D-rings which causes air leaking

- Can fly away if not properly anchored into the ground

- No water capture ability so there could be runoff concerns

- Electricity needed and will need to be kept away from the water

Cost and Installation

Materials: $680

Installation: DIY

Duration of Install: 30 Minutes

Helpful Video

#8 - Wash Bay Mats

Wash mats are not really an enclosure but they do help contain the wash down water and debris. These are fully deployed with air berms on the sides that inflate to form a containment area. The vehicle is then driven onto the wash bay mat and then it's ready for cleaning. They are also used for decontamination applications where the chemicals being are not allowed to make their way into the water system or the ground. As an option they are available with foam insert berms in place of the air filled berms. A surface level liquid skimming pump is placed at a low point to act as a liquid collection point. All collected wash water is then pumped into a customer-supplied storage tank or a wash water recovery system. When done, you simply roll or fold the mat into a compact size for transport between jobs.

Considerations

PROS

- Great for containment of water and debris

- Inexpensive

- Very easy to setup, inflate, take down, and store

- Very easy to reposition elsewhere on the site

- Lightweight

- Compact storage

CONS

- Can fly away if the wind gets under it with no load / water

- Material could rip or be worn out from sharp object being loaded

- There are no side walls to contain overspray so only drip water is collected

Cost and Installation

Materials: $100-1,000

Installation: DIY

Duration of Install: 30 Minutes

Helpful Video

#9 - Wash Bay PVC Panels

PVC panels are common for existing rigid walls that are already in place. These are common for facilities or garages that have a stud wall, concreate wall or similar wall that just needs to be covered. The wash bay liner panels are then placed on the surface of those walls to protect the walls from water damage. This type of wash bay enclosure is really more of a component of an existing wash bay than a full turn key solution.

Moisture, soap, and harsh cleaning chemicals can wear away at walls with tile, grout, FRP, HDPE board, and painted surfaces. This PVC car wash panel helps protect those materials. The panels are inert and impenetrable to water, meaning they'll never rot, rust, corrode, or sustain the advancement of mold and mildew. So if you already have a structure in place and just need to protect it then this is a good option.

Considerations

PROS

- Great for protecting existing structure from water damage

- Wall panels are easily cleaned and disinfected

- Interlocking tongue & groove design makes for quick install

CONS

- Not a turnkey solution but rather just an addon for a wash bay enclosure

Cost and Installation

Materials: $300-$10,000

Installation: DIY or Handyman

Duration of Install: 1-5 days

Helpful Video

#10 - Canopy Carport Wash Bays

Outdoor wash bays need to be sturdy and they need to be able to withstand the elements such as wind and rain. Using freestanding vehicle wash bay canopies is one such solution. They offer protection from the elements 365 days of the year. So no matter what the weather you can keep washing down vehicles and equipment. A vehicle wash bay canopy can be modular, so if required you could have multiple bays separated by a polycarbonate wall system. This helps prevent any overspray and allows you to wash a vehicle in one bay, whilst drying or cleaning the interior of another vehicle in another. The vehicle wash bay canopies come with a variety of side wall paneling options as well depending on your requirements. For instance they can be clear for a line of sight or opaque to block out the sun.

Considerations

PROS

- Great outdoor locations

- Protection from harsh weather unlike inflatable wash bays

- Hard side walls wont blow around in the wind

- Roof can be translucent to allow light inside the enclosure

- Can be attached to adjacent units for multiple wash bays

CONS

- Limited in size so it wont accommodate very large equipment

- Installation crew is ideal versus DIY install

- Panels are rigid so they could be damaged if you hit them hard

Cost and Installation

Materials: $5,000 to $30,000

Installation: $800 to $7,000

Duration of Install: 1-7 days

#11 - Freestanding Wash Bay Curtains

When there is no structure to attach to then bottom up or floor up wash bay enclosures can be used. These are made from galvanized steel hardware and reinforced VCP curtains. These curtains are slick and can be wiped down with ease and the hardware can be assembled with only basic tools. The curtain side walls can be fixed in place or they can be mounted with curtain track that has rollers which allows for side to side movement of the curtains. This movement allows for the curtains to open for people of product. This setup is much less expensive that rigid walls and it is stronger than an inflatable wash bay curtain.

The freestanding wash curtain bays can also be broken down and relocated as needed. Though they are not really considered portable due to the amount of effort it would take to break them down, they can be moved.

Considerations

PROS

- Great for locations that have overhead obstructions like gantry cranes

- Curtains are slick and easily wiped clean

- Can be broken down and relocated if needed

- Curtains roll open to allow product and people inside

- More professional than inflatable versions

CONS

- Not truly portable due to the effort required for breaking it down

- Limited to 15' in height

- Anchor bolts required on systems that are not four sided

Cost and Installation

Materials: $1,500-$6,000

Installation: DIY or Handyman

Duration of Install: 1-2 days